- December 2, 2024

- Posted by: PQS_Mitra_Main_Access

- Categories:

Introduction

The automotive industry is driven by precision, consistency, and continuous improvement. Behind every component, process, and finished vehicle is a rigorous quality system ensuring products meet exacting standards. For professionals working in this dynamic industry, understanding and applying quality methodologies isn’t just a requirement—it’s a necessity. One of the key quality frameworks is IATF 16949, a global standard that integrates the structure of ISO 9001 with specific requirements for the automotive sector.

At the heart of IATF 16949 are the Core Tools—a set of essential methodologies that help manufacturers and suppliers design, analyze, monitor, and improve their processes. These tools are not just theoretical—they’re the backbone of day-to-day quality assurance in automotive environments. If you’re involved in automotive production, engineering, quality control, or supplier management, knowing these tools is vital for contributing effectively to your organization’s quality goals.

What Are the IATF 16949 Core Tools?

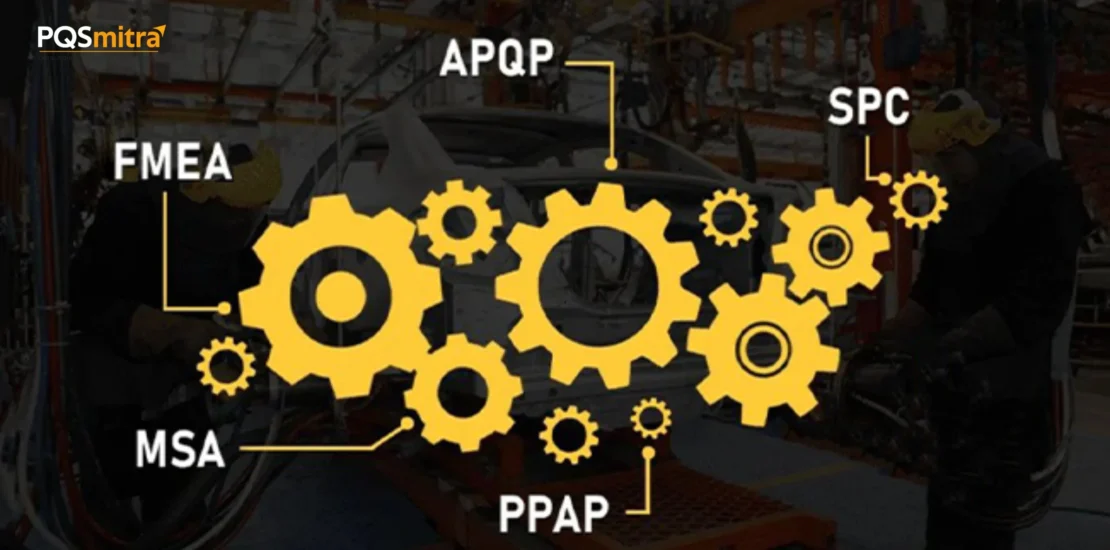

The Core Tools were developed jointly by AIAG (Automotive Industry Action Group) and major automotive manufacturers. They provide a common framework for quality planning and problem-solving across the supply chain. These five tools form the foundation of quality management systems under IATF 16949:

- APQP (Advanced Product Quality Planning)

APQP ensures that product development processes are well planned and executed. It lays out a structured path from initial concept to full-scale production, minimizing risks and ensuring product quality at every stage. - PPAP (Production Part Approval Process)

PPAP validates that production processes can consistently produce parts that meet customer specifications. It’s a critical checkpoint for suppliers before mass production begins. - FMEA (Failure Modes and Effects Analysis)

FMEA is a risk assessment tool used to identify potential failures in a process or product and take proactive steps to mitigate them. Both Process FMEA and Design FMEA are widely used to improve reliability. - MSA (Measurement Systems Analysis)

MSA evaluates the accuracy, precision, and consistency of measurement systems used in quality control. It ensures the data used for decision-making is trustworthy. - SPC (Statistical Process Control)

SPC uses statistical methods to monitor and control manufacturing processes. It helps detect variations and prevent defects, leading to higher quality and efficiency.

These tools aren’t isolated checklists—they’re interrelated components that support a company’s goal of zero defects and robust quality systems. When used together, they empower organizations to predict and prevent issues rather than react to them after they occur.

Why Mastering These Tools Is Crucial for Automotive Companies

For companies operating within the automotive supply chain, IATF 16949 certification is often a basic requirement to do business. But merely having a certificate isn’t enough—what really matters is the ability to implement its core elements effectively. This is where the Core Tools come in.

- Customer Satisfaction: OEMs and Tier-1 suppliers demand reliable products that meet exact specifications. Core Tools help ensure consistency in product quality and performance.

- Compliance & Audits: Certification bodies and customers audit your systems regularly. Demonstrating strong command over Core Tools is crucial to passing these audits without non-conformities.

- Cost Reduction: Preventing defects before they occur means fewer recalls, rework, and warranty claims. That translates directly to cost savings and enhanced profitability.

- Data-Driven Decision Making: Tools like SPC and MSA encourage data-based analysis over assumptions. This leads to more informed decisions and more predictable outcomes.

- Continuous Improvement Culture: These tools create a mindset where employees look for opportunities to refine processes, reduce waste, and improve performance.

Training Required to Apply Core Tools Effectively

The Core Tools are technical in nature, and their true value comes from using them correctly and consistently. Simply reading about FMEA or SPC isn’t enough—hands-on understanding is needed to apply these tools in real-world situations.

Most organizations recognize that Core Tools must be more than just documented—they need to be lived through training and practice. Teams at all levels, from engineers to supervisors, benefit from structured learning that breaks down each tool with examples, case studies, and implementation techniques.

The Role of Training

Structured training programs for IATF 16949 Core Tools help professionals build deep expertise, enabling them to contribute more effectively to quality objectives. Whether onsite or online, such training sessions focus on:

- Explaining the purpose and structure of each Core Tool

- Providing guidance on documentation and templates

- Demonstrating real-life examples of implementation

- Teaching participants how to evaluate effectiveness and improve

Training can also help align teams by creating a common understanding of terminology and expectations. In industries like automotive manufacturing, where time and precision are critical, such alignment minimizes communication gaps and enhances coordination.

Participants who complete Core Tool training become valuable assets to their organizations. They can lead quality planning activities, conduct internal assessments, and drive corrective actions with confidence and clarity.

Conclusion

IATF 16949 Core Tools are the building blocks of a strong automotive quality system. They guide teams in planning, validating, measuring, and improving their processes, which ultimately leads to safer, better, and more consistent products. For any company in the automotive supply chain, understanding and applying these tools is non-negotiable.

Comprehensive training ensures these tools are applied effectively and consistently throughout the organization. It empowers professionals to not only comply with industry expectations but also to push the boundaries of quality excellence.

At PQSmitra, we offer expert-led training programs in IATF 16949 Core Tools that help organizations master these essential methods. Whether you’re looking to strengthen your internal quality team or prepare for certification, our training programs are designed to meet your business goals with the flexibility of online and onsite options.

Leave a Reply Cancel reply

Kindly submit a business inquiry online and we will get back to you!

OR

Call us on 022-2893 8687 | +91-9820204373