- January 9, 2025

- Posted by: PQS_Mitra_Main_Access

- Category: PPAP Documentation

Introduction

In the world of quality management, professionals are tasked with ensuring that products, services, and processes meet specific standards of excellence. Achieving this requires the ability to identify issues, analyze data, and implement corrective actions. One of the most powerful ways to do this is by using the 7 QC Tools—a set of simple, effective techniques that have been proven to support quality improvement and problem-solving across various industries.

The 7 QC Tools are foundational to quality control and continuous improvement. These tools are highly accessible, requiring minimal technical knowledge, yet they deliver powerful insights into performance, defects, and potential areas for improvement. Whether you’re in manufacturing, service delivery, or any other sector, mastering these tools is a must for quality management professionals who want to drive change, improve processes, and maintain high standards of excellence.

In this blog, we will explore what these 7 tools are, how they are used, and why mastering them is essential for anyone in the quality management field.

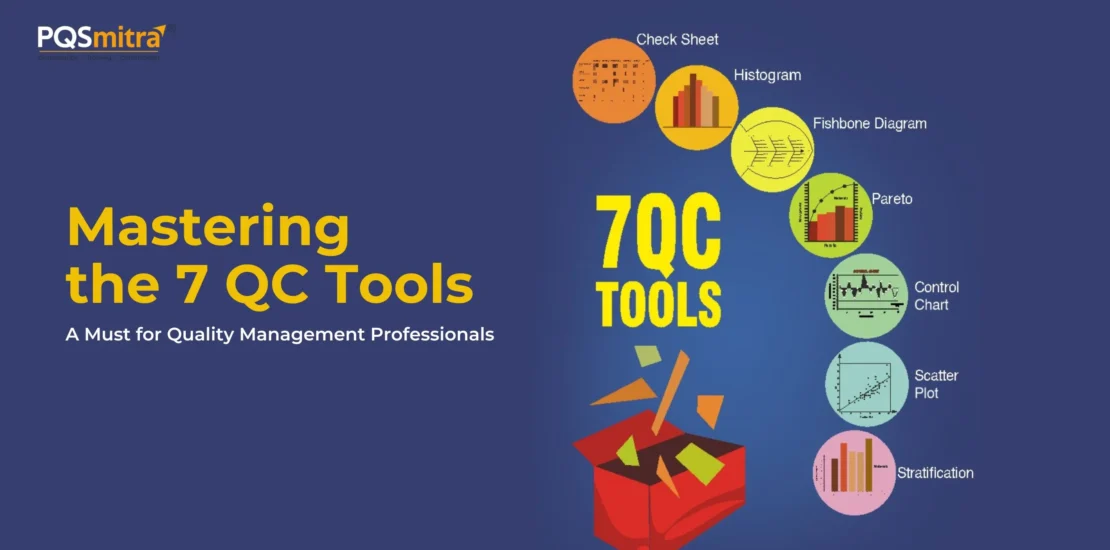

The 7 QC Tools: Overview

The 7 QC Tools, also known as the “basic” tools of quality, are fundamental techniques that can be applied to almost any industry or business process. These tools are straightforward to use, yet they allow quality professionals to uncover valuable insights into performance, identify trends, and take corrective actions. The 7 tools include:

- Cause-and-Effect Diagram (Fishbone Diagram)

Also known as the Ishikawa diagram or fishbone diagram, this tool is used to identify the root causes of a problem. The diagram resembles a fish’s skeleton, with the “head” representing the problem and the “bones” representing potential causes, which are categorized into main categories like people, process, equipment, and materials. It helps teams organize their thoughts and explore various factors contributing to a problem. - Check Sheet

A check sheet is a simple tool used for data collection. It’s essentially a form where you can tally occurrences of a particular event, defect, or issue. By collecting data over time, quality managers can easily spot trends and patterns, providing valuable insights into areas that need attention. - Control Chart

Control charts are used to track data points over time to monitor the stability and variation in a process. This tool helps quality professionals determine if a process is in control or if there are fluctuations or irregularities that need addressing. Control charts are particularly useful for monitoring processes in manufacturing and service delivery. - Histogram

A histogram is a graphical representation of data distribution. By showing how data is spread across different categories, histograms allow professionals to visualize the frequency of occurrences in a set of data. This tool is useful for identifying patterns and variations that may indicate quality issues. - Pareto Chart

A Pareto chart is based on the Pareto principle, which suggests that roughly 80% of problems are caused by 20% of the causes. The chart displays data in descending order, helping quality managers identify the most significant issues to address first. By focusing on the most impactful problems, organizations can prioritize corrective actions and improvements more effectively. - Scatter Diagram

A scatter diagram (or scatter plot) is used to display the relationship between two variables. By plotting data points on a graph, this tool helps quality professionals identify correlations or trends that might not be immediately apparent. Scatter diagrams are particularly useful for determining the impact of one factor on another, such as how changes in a process might affect output quality. - Flowchart

A flowchart is a visual representation of a process, showing the steps involved and the decision points along the way. This tool helps quality professionals understand how processes function and where potential inefficiencies or bottlenecks might exist. Flowcharts are essential for mapping out workflows and identifying opportunities for process improvements.

Why Mastering the 7 QC Tools Is Essential

The 7 QC Tools are more than just a set of techniques—they are a mindset. Mastering these tools empowers quality management professionals to approach problems systematically, diagnose issues, and drive continuous improvement. Let’s explore why mastering the 7 QC tools is essential for anyone in quality management.

- Simplifies Complex Problems

Quality problems can often seem overwhelming, especially when they involve multiple variables and interrelated factors. The 7 QC tools help break down these complex issues into manageable components, making it easier to identify the root causes and address them effectively. - Promotes Data-Driven Decisions

In quality management, decisions should be based on data, not assumptions. Tools like check sheets, control charts, and histograms help collect and analyze data, enabling quality professionals to make informed decisions based on facts rather than guesswork. - Improves Problem-Solving Capabilities

By using these tools, quality management professionals can systematically address issues and prevent them from recurring. Whether it’s identifying inefficiencies in a process with a flowchart or pinpointing the most common defects with a Pareto chart, these tools allow for structured problem-solving that leads to effective, long-lasting solutions. - Drives Continuous Improvement

The 7 QC tools are instrumental in supporting the continuous improvement process, a cornerstone of many quality management systems (like Six Sigma and Lean). These tools help monitor processes, identify areas for improvement, and track progress over time. This ongoing cycle of improvement helps organizations remain competitive and enhance customer satisfaction. - Builds a Quality-Oriented Culture

Mastering the 7 QC tools encourages a culture of quality within an organization. By empowering employees at all levels to use these tools, organizations can foster a mindset of quality improvement and encourage proactive problem-solving. This can lead to a more engaged and effective workforce.

The Role of Training in Mastering the 7 QC Tools

Mastering the 7 QC tools requires more than just theoretical knowledge—it requires hands-on practice and the ability to apply the tools in real-world scenarios. Our training programs offer comprehensive guidance on how to effectively use each of the 7 QC tools. Through both online and onsite training, we equip professionals with the skills they need to apply these tools in their day-to-day work.

Our certification-based training programs focus on practical, real-world applications of the 7 QC tools, helping professionals develop a deep understanding of how to integrate these tools into their quality management systems. Whether you’re an individual looking to enhance your skills or an organization aiming to improve its processes, our training programs provide valuable insights and practical knowledge.

Leave a Reply Cancel reply

Kindly submit a business inquiry online and we will get back to you!

OR

Call us on 022-2893 8687 | +91-9820204373